Tygon A-60-G

Features and Benefits

• Superior weathering

• Abrasion resistant

• Outstanding flexural fatigue resistance

• Wide temperature range (-75°F to 275°F)

• Low gas permeability versus rubber tubing

• Ozone* and UV light resistant

Typical Applications

• Soap and disinfectant dispensing

• Cleaning chemical transfer

• Caustic chemical dispensing

• Plating and etching chemicals

• Glass and window wash systems

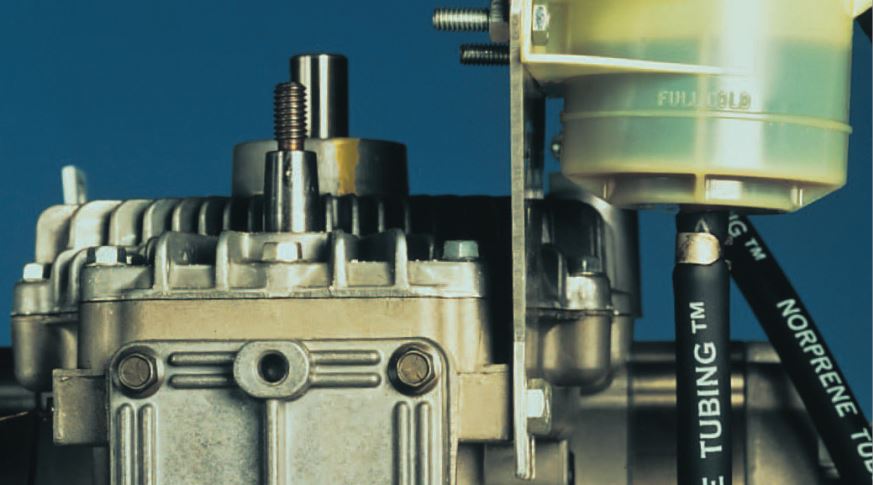

• Vacuum pumps

* 300 pphm